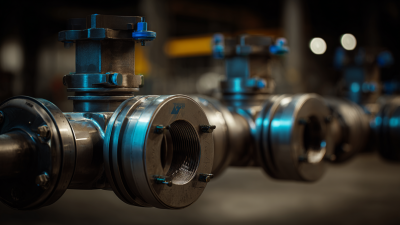

In industrial applications, optimizing the performance of machinery is crucial for efficiency and reliability, and one often overlooked component is the slide gate valve. This critical device plays a significant role in the control of flow within various systems, ensuring that materials move seamlessly from one point to another. However, to fully harness the benefits of slide gate valves, understanding effective techniques for their maximization is essential. By focusing on maintenance practices, choosing the right materials, and implementing innovative design approaches, industries can enhance the functionality of these valves, resulting in improved productivity and reduced operational costs. This blog will explore the multifaceted advantages of slide gate valves and discuss strategies that can be employed to elevate their performance in demanding industrial environments.

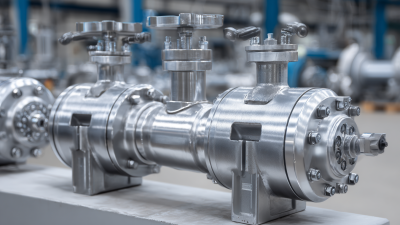

When selecting slide gate valves for industrial applications, it's crucial to consider several key factors to ensure optimal performance. According to a recent report by the Valve Manufacturers Association, the right valve can reduce maintenance costs by up to 30% and improve process efficiency significantly. The first step in selecting a slide gate valve is to assess the specific application requirements, including the type of media being handled, pressure and temperature conditions, and flow rates. Understanding these parameters allows for a more informed choice regarding materials and the design of the valve.

When selecting slide gate valves for industrial applications, it's crucial to consider several key factors to ensure optimal performance. According to a recent report by the Valve Manufacturers Association, the right valve can reduce maintenance costs by up to 30% and improve process efficiency significantly. The first step in selecting a slide gate valve is to assess the specific application requirements, including the type of media being handled, pressure and temperature conditions, and flow rates. Understanding these parameters allows for a more informed choice regarding materials and the design of the valve.

Tip: Always consult the manufacturer's specifications to ensure compatibility with your application. For instance, stainless steel valves are recommended for corrosive materials, while cast iron may be suitable for more abrasive environments.

Additionally, factor in the installation and operational settings. The orientation of the valve can influence its performance—vertically installed valves often provide better sealing for certain applications. It's also essential to consider the potential for future upgrades or changes in the operation, as a versatile design can accommodate evolving needs.

Tip: Implement thorough testing of the valve under actual operating conditions to assess its performance and reliability before full-scale deployment. According to industry standards, a well-tested slide gate valve can enhance system integrity and lead to a more streamlined production process.

In industrial applications, the performance of slide gate valves is influenced by several key factors that engineers and operators must consider for optimal functionality. One crucial aspect is the proper sizing and selection of the valve to match the flow requirements of the application. An undersized valve can lead to increased pressure drop and inefficient flow, while an oversized valve can result in unstable flow control. Furthermore, the material of construction plays a significant role in maintaining the integrity of the valve under varying pressures and temperatures, which is essential for long-term operation.

Another critical factor is the maintenance of the valve, which directly impacts its operational reliability. Regular inspections and timely replacement of wear components are necessary to prevent leaks and ensure seamless operation. The design of the valve also affects its performance; features such as sealing mechanisms and actuator types should be optimized to enhance responsiveness and reduce wear. By addressing these factors, industrial facilities can significantly improve the performance of slide gate valves, leading to increased efficiency and reduced operational costs.

| Key Factor | Description | Impact on Performance | Recommended Technique |

|---|---|---|---|

| Material Selection | Choosing the right materials for the valve construction | High durability and resistance to corrosion | Use stainless steel or specialized alloys |

| Seal Integrity | Effectiveness of seals to prevent leaks | Minimized leakage and improved operational efficiency | Regular inspection and replacement of seals |

| Operating Pressure | Pressure range in which the valve is operated | Influences flow rate and system efficiency | Optimize pressure settings during design |

| Maintenance Schedule | Frequency of maintenance and checks | Reduces downtime and enhances reliability | Implement a regular maintenance program |

| Actuator Type | Type of actuator used for valve operation | Affects the speed and precision of valve operations | Select electronic actuators for quick response |

Routine maintenance is crucial for ensuring the optimal functionality of slide gate valves in industrial applications. Industry reports indicate that approximately 30% of valve failures are attributed to inadequate maintenance practices. Regular inspections and servicing can minimize such failures, potentially increasing operational efficiency by up to 15%. By performing scheduled maintenance checks, operators can identify signs of wear, corrosion, or obstructions that could lead to significant downtime if left unaddressed.

One effective routine maintenance technique involves the lubrication of moving parts to reduce wear and tear. According to the Valves and Actuators Market report, proper lubrication can enhance the lifespan of valves by nearly 25%. Additionally, implementing a systematic approach to cleaning valve mechanisms can prevent build-up of debris, which, if ignored, could obstruct flow and lead to pressure drops. Ensuring that sealing components are in good condition is also vital; replacing worn seals promptly can prevent leaks and further improve the system's reliability. Continuous investment in maintenance training for personnel can result in further optimizing valve performance, ensuring that facilities operate smoothly and efficiently.

Slide gate valves are essential components in various industrial applications, yet their efficiency can often be compromised by common issues. One prevalent problem is wear and tear caused by abrasive materials flowing through the valve. Over time, this can lead to misalignment and leaks, hindering the valve's performance. Regular maintenance, including scheduled inspections and replacement of worn components, can mitigate these issues and prolong the lifespan of the valve.

Another challenge affecting slide gate valve efficiency is improper actuation. If the actuator is not well calibrated or maintained, it can cause sluggish operations, leading to delays in processing and potential safety hazards. Implementing an automated monitoring system can enhance actuation reliability, ensuring timely and accurate operations. Additionally, ensuring that the valve is correctly sized for the application can prevent unnecessary strain and promote smooth operation in demanding environments. By addressing these common issues proactively, industries can significantly enhance the performance and reliability of slide gate valves in their processes.

In the realm of industrial applications, innovative technologies play a crucial role in enhancing the performance of slide gate valves. As industries face challenges such as increasing efficiency and reducing emissions, the integration of advanced technologies like sustainable zero leak systems becomes paramount. These systems not only minimize leakage but also support environmental goals by significantly lowering harmful atmospheric emissions. Such advancements are paving the way for more sustainable operations across sectors.

Moreover, the shift towards automation and smart control technologies is transforming how slide gate valves function within complex systems. By employing sophisticated monitoring and control mechanisms, industries can achieve greater precision in valve operations, resulting in improved reliability and performance. This evolution in valve technology aligns with broader trends in the energy market, where companies are prioritizing strategic resilience amidst fluctuating demands and regulatory pressures. The ongoing innovations in valve designs and functionalities are indispensable for maximizing operational efficiency and ensuring compliance with environmental standards.

Same Day Shipping

ISO Certified Production