In the realm of industrial fluid control, the actuated ball valve stands out as an essential component, combining reliability, efficiency, and precision. As industries evolve, the demand for high-quality actuated ball valves has surged, prompting manufacturers to innovate and enhance their offerings. This blog delves into the features and applications of the best actuated ball valves, providing valuable insights into their operational advantages and use cases across various sectors. Additionally, we will guide you through the process of selecting a reputable manufacturer, outlining key criteria that ensure the quality and performance of the valves.

Whether you are in the market for an actuated ball valve for process automation, flow regulation, or safety applications, understanding the fundamentals will empower you to make informed decisions that align with your operational needs. Join us as we explore the exciting world of actuated ball valves and uncover solutions tailored to your specific requirements.

Actuated ball valves are revolutionizing fluid control across various industries, and as we look toward 2025, significant trends and innovations are shaping their technology. One major advancement is the integration of smart sensors and IoT connectivity, which allows for real-time monitoring and control of valve operations. This technology not only enhances efficiency but also reduces downtime by enabling predictive maintenance. As industries increasingly adopt automation, actuated ball valves are becoming more sophisticated, offering enhanced functionality and adaptability to complex systems.

Tip: When selecting an actuated ball valve for your application, consider compatibility with existing systems and the specific requirements of your process. This includes flow rates, pressures, and the types of fluids being handled. Proper calibration and installation are crucial for maximizing the performance of these advanced valves.

Another trend is the focus on energy efficiency and sustainability. Manufacturers are striving to produce valves that consume less energy and minimize waste during operation. The development of materials that can withstand higher pressures while remaining lightweight is also paramount, allowing for more robust and versatile designs. This shift not only benefits the environment but also meets the growing demands of industries focused on sustainability.

Tip: Stay informed about emerging materials and technologies in the market to ensure that your choice of actuated ball valve aligns with the industry’s best practices for sustainability. Regular training and updates on the latest innovations can significantly enhance operational safety and efficiency.

| Feature | Description | Applications | 2025 Trends |

|---|---|---|---|

| Material | High-performance alloys for better durability | Oil and gas, water treatment | Shift toward corrosion-resistant materials |

| Actuation Type | Electric, pneumatic, and hydraulic options | Industrial automation, HVAC systems | Increased demand for electric actuators |

| Control Features | Smart control systems with IoT integration | Smart factories, remote monitoring | Growing trend of remote diagnostics |

| Size Range | Available in various sizes from small to large | Manufacturing, chemical processing | Customization options for diverse applications |

| Automation Level | Fully automated systems vs. manual controls | Food and beverage, pharmaceuticals | Increased focus on fully automated solutions |

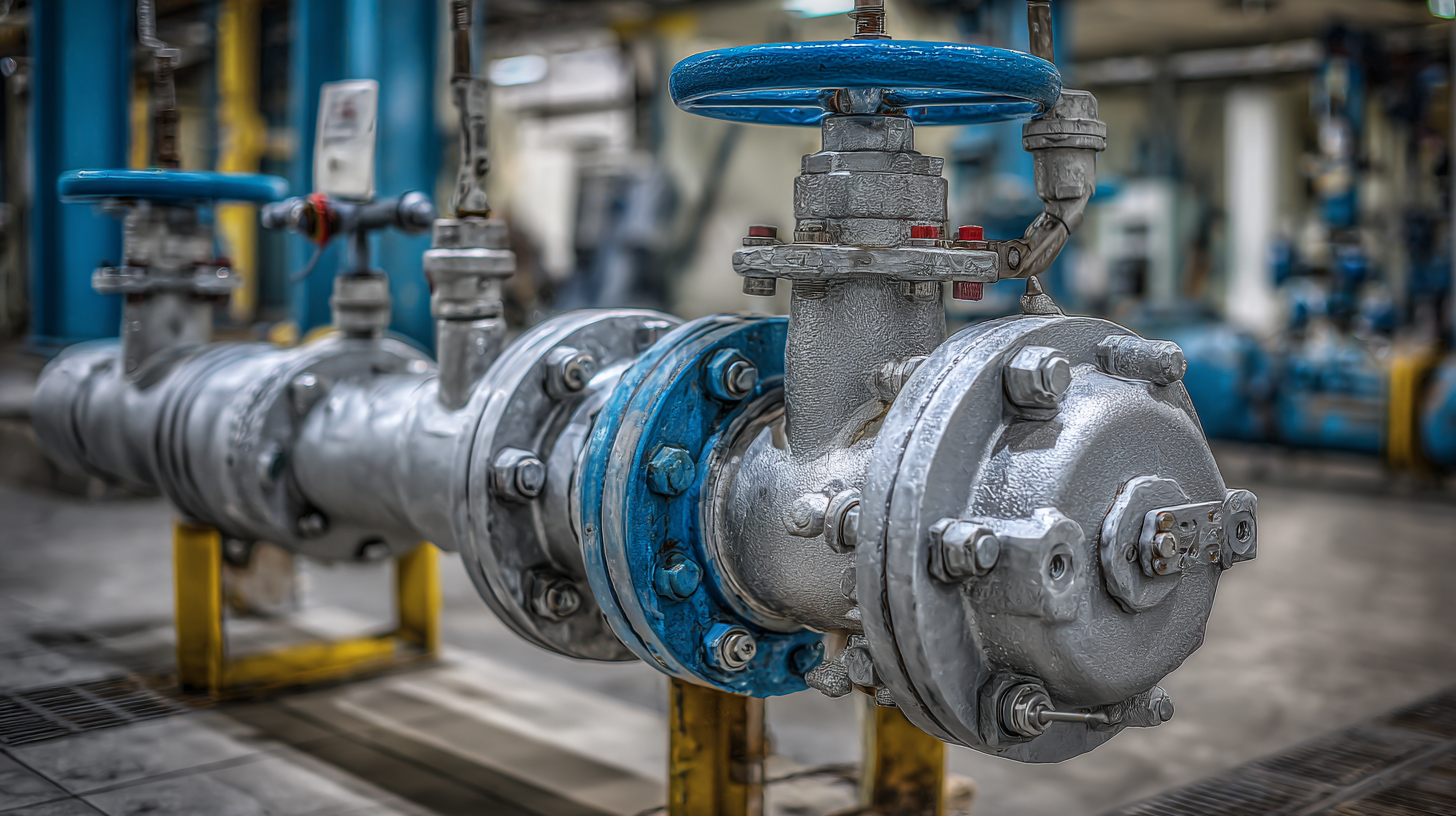

When exploring the realm of actuated ball valves, there are several key features that contribute to enhanced performance and efficiency. One notable feature is the precise control over flow regulation. With advanced actuator technology, these valves allow for accurate modulation of flow rates, ensuring that systems operate at optimal levels. This precision not only minimizes waste but also significantly reduces energy consumption, making actuated ball valves an eco-friendly choice for various industrial applications.

Another essential characteristic is the durable construction of top actuated ball valves. Typically made from high-grade materials such as stainless steel or carbon steel, these valves are designed to withstand extreme temperatures and pressures. Their robust design minimizes downtime caused by wear and tear, thus enhancing the overall reliability of the system. Additionally, many modern actuated ball valves come with smart features such as remote monitoring and diagnostics, allowing for real-time assessments and adjustments, which further improves operational efficiency in complex processes.

The actuated ball valve market has witnessed significant growth in recent years, driven by advancements in automation and increasing demand for efficient process control in various industries. According to a recent report by MarketsandMarkets, the global actuated ball valve market is projected to reach USD 6.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.9% from 2020 to 2025. This growth is largely attributed to the rising need for reliable and accurate flow control systems in sectors such as oil and gas, water and wastewater treatment, and power generation.

Furthermore, the adoption rates of actuated ball valves are reflecting these market trends. A report by Technavio highlights that the oil and gas sector is expected to dominate the market, accounting for over 40% of the total market share by 2023. The increasing investments in infrastructure and modernization of existing facilities are propelling this growth. Additionally, the trend towards integrating Industry 4.0 technologies into manufacturing processes is further boosting the need for smart actuated valve solutions that enhance operational efficiency and reduce downtime. As industries continue to evolve, the importance of actuated ball valves in automating system operations will only increase, paving the way for further innovations and applications.

Actuated ball valves have become essential components in various industrial applications due to their efficiency and reliability. In the oil and gas sector, for instance, these valves play a crucial role in controlling the flow of crude oil and natural gas through pipelines. With their ability to provide quick action and automation, actuated ball valves help maintain operational safety and efficiency while reducing the potential for leaks and other hazards. Their robust design can withstand extreme pressures and harsh environmental conditions, making them ideal for upstream and downstream processes.

In water treatment facilities, actuated ball valves ensure precise control over the treatment process. They are used to regulate the flow of water during various stages, such as filtration and chemical dosing, helping to maintain water quality and compliance with safety standards. Furthermore, their automation capabilities allow for remote monitoring and operation, which can significantly enhance the operational efficiency of water treatment systems. Overall, the versatility and effectiveness of actuated ball valves make them a preferred choice across multiple sectors, from oil and gas to water treatment, reflecting their critical role in modern industrial processes.

When selecting the right actuated ball valve for your applications, understanding the specific features and their practical implications is essential. Recent studies highlight that the integration of advanced technologies can significantly enhance the performance and reliability of these valves. For instance, the optimization of valve placement can minimize potential leakage and improve flow efficiency, similar to initiatives in cardiovascular procedures where precision is key.

**Tips for Selection:** Start by evaluating the valve’s material compatibility with your system’s fluids. This ensures longevity and reduces the risk of chemical reactions that may impair functionality. Additionally, consider features such as automation capabilities and the ease of integration with existing systems, which can lead to substantial operational efficiencies.

Furthermore, using a selection checklist tailored to your specific needs can streamline the decision-making process. Assess factors like valve size, pressure ratings, and actuator types, which are essential parameters in ensuring optimal performance. By following these guidelines, you can confidently choose an actuated ball valve that meets both current demands and future scalability for your projects.

Same Day Shipping

ISO Certified Production